These 2 Isuzu Dmax builds are now officially ready to head off to their new jobs as site workers! Our reputable team built these 2 vehicles using only the most durable gear. Good project management aided in achieving the best results for our customer.

The Dmax’s Bull bar, Battery Isolation and Driving Lights

On these two builds we installed them both with Opposite Lock Post Bull bar’s to keep them protected by the harsh conditions of a mine site and these bars were then colour matched to tie in the look with the vehicles body colour!

On the bull bar we have also installed a pair of Ultra Vision Raptor LED 7″ Driving Lights along with an in-cab switch to flick them on and off easily every time the operator needs some more light on the situation! In the picture gallery, you will also notice a battery isolator located on the passenger side of the bull bar.

Safety and Communication

On site, there are precautions and regulations taken to have vehicles authorised to be able to use. Since these 2 builds are heading to work, we installed a multitude of Safety Equipment amongst the builds. Our team installed the vehicles with Redarc Tow Pro Elite V3 Electric Brake Controller’s to provide the vehicles operator with smooth and confident braking, Daytime Running Light Controller’s to ensure the vehicles headlights are switched on whenever the vehicles ignition is on and also Hand Brake Alarm’s which provides an audible warning if the vehicles door is open but the hand brake is not applied.

Along with the above modifications, the vehicles were also equipped with a 4.5kg Fire Extinguisher, a First Aid Kit and as you can see, they have yellow wheel nut indicators which provide a constant visual indication of loosening wheel nuts or overheating brakes.

Vehicles heading to site also require a mine bar to be installed. These bars feature a reverse alarm, rear stop/tail lights, indicator lights, supplementary reverse lamps and work lights.

For the communication side of things, we installed a GME UHF CB to the inside of the cab, and a GME antenna to the bull bar of the 2 vehicles to promote communication amongst all vehicles on site.

Air Intake and Suspension Upgrades

Both these Dmax’s were installed with a Safari 4×4 Engineering V-Spec Snorkel which is essential on a dusty mine site to raise the vehicles air intake. This ensures the Dmax’s are receiving cool, clean air through their air intake.

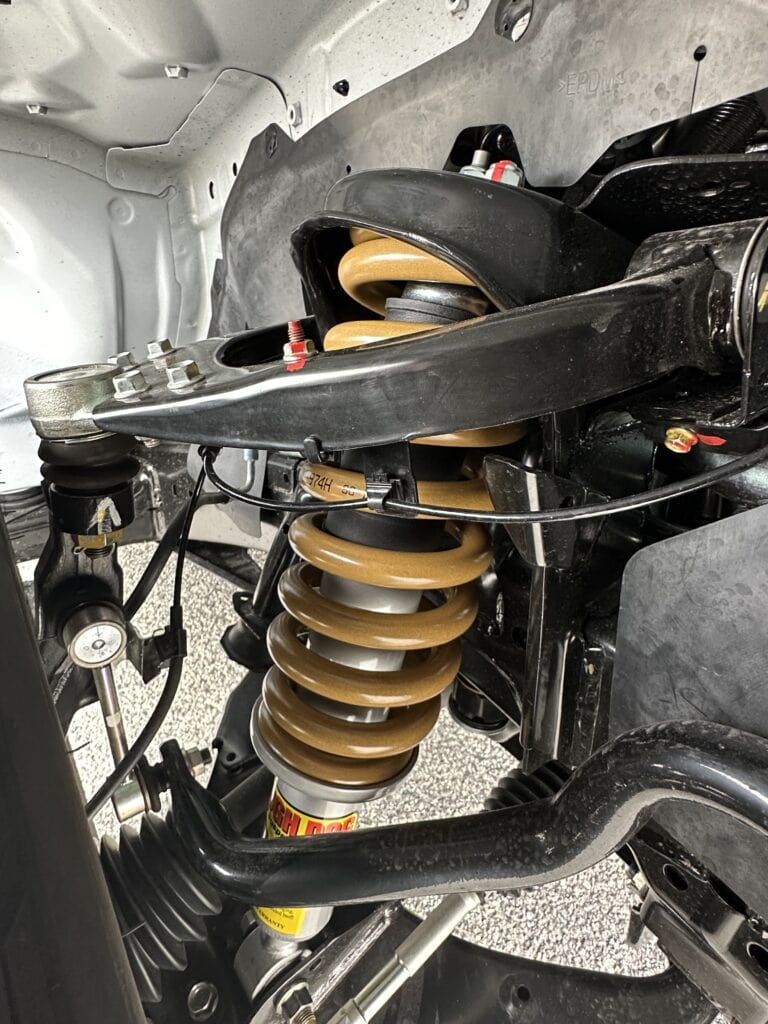

As mine sites are mainly covered in dirt and are corrugated in areas, we installed these builds with a full Tough Dog Suspension Kit. This will ensure the vehicles drivability is maintained, making for a safe and comfortable drive for any of the vehicles operators.

Long Range Fuel Tank and Preline Fuel Filter Kit

The Dmax’s were each fitted with Brown Davis 140L Poly Replacement Fuel Tanks, ensuring that when extra fuel is required, it isnt a hassle for the operator to get their hands on. With a long range tank, the fuel is stored in the upgraded fuel tank rather than using multiple jerry cans or getting to a servo and filling up your tank more often than required. This 140L tank Efficiency is key.

When you head to a remote location such as a mine site, you can get fuel but often you have no idea about the quality of fuel you are putting into your tank. The Direction Plus Preline Filters we installed onthese 2 builds are designed specifically to cope with extreme weather conditions and poor fuel quality. They ensure a high degree of water separation and particle pre-separation.

Overall, these 2 Isuzu Dmax builds turned out great, and if you are interested in enquiring about mine spec builds for your fleet, reach out to us today for more information.